CITIZEN Low Frequency Vibration Cutting-LFV

1. What is LFV?

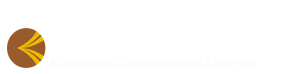

The low-frequency vibration cutting technology is a technology that moves the servo axis (X, Z) to the axis direction to make the vibration synchronized with the spindle rotation for cutting.

2. When cutting, by setting the “idle vibration” time, the chip is broken up and then intermittently eliminated.

3. It can be used for a variety of machining shapes and cutting materials. It is most suitable for the machining of hard-to-cut materials such as nickel-chromium alloys, stainless steel, and copper. technology.

2. What are the advantages of the LFV function?

1. Solve the problem of entanglement, reduce stop during processing, prevent mechanical failure, and improve product yield.

2. Solve the tool wear caused by iron filings entanglement, and suppress sudden tool damage.

3. Air vibration can suppress processing temperature and increase tool life.

4. Reduce the cutting capacity after chip breaking, reduce the number of iron chip cleaning, and reduce the environmental load.

3. How many processing modes does LFV have?

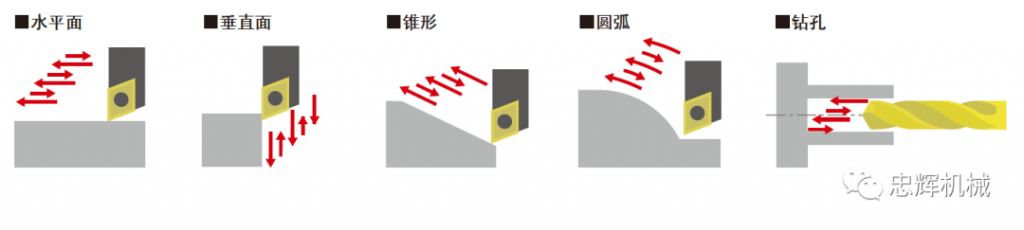

In addition to the linear machining surface, the vibrating cutting surface can also be processed with tapers, arcs, and drilling.

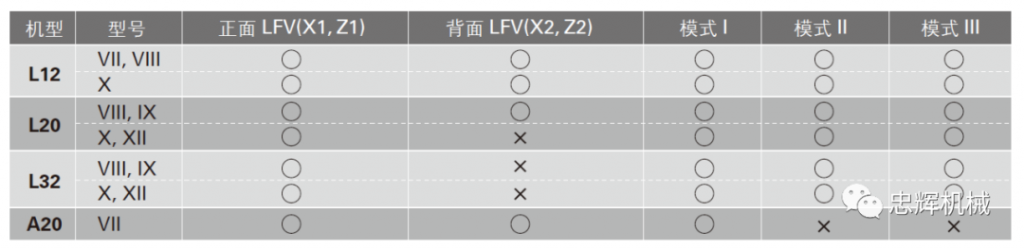

4. LFV can be equipped with models